The data you collect and the manner in which you allocate costs can greatly impact the usefulness of your ABC model. It’s worth noting that while ABC can offer more detailed insight into your costs, it’s not always necessary or beneficial for every business. ABC can be more time-consuming and QuickBooks ProAdvisor expensive to implement than traditional costing methods, so it’s generally more suitable for larger businesses with diverse products and processes. Like any costing method, it’s important to understand the strengths and weaknesses of ABC and decide if it’s the right fit for your organization. That means you can more accurately analyze your spending and price your products.

A: How to make your communication more Accurate.

For example, while traditional methods might allocate electricity costs evenly across all products, ABC assigns these costs based on actual machine hours or specific production requirements. Activity-Based Costing (ABC) is an accounting process that assigns overhead and indirect costs to specific products and services by focusing on the causal relationships between costs, activities, and final outputs. This approach aims to achieve accuracy in cost data, resulting in true costs, particularly for companies with complex production processes. With the cost pools and drivers in place, the next step is to calculate the cost driver rates for each cost pool.

Get manufacturing know-how delivered to your inbox!

It is very common to have separate cost pools for each product line, since costs tend to occur at this level. Such costs can include research and development, advertising, procurement, and distribution. Similarly, you might consider creating cost pools for each distribution channel, or for each facility. If production batches are of greatly varying lengths, then consider creating cost pools at the batch level, so that you can adequately assign costs based on batch size.

How we ensure our content is accurate and trustworthy?

But in practice there will be differences in set-up time, production run, and meeting a delivery order for the product or process, as well as for different products. ABC provides more reliable data relating to activity driving costs which helps managers to improve product and process value. Under Conventional or Traditional Costing System, overhead expenses are identified initially with the cost centres which comprise of both the production departments and service departments. The costs of service departments are then distributed, on some equitable bases, to the production departments.

In the realm of accounting and financial management, the concept of Activity Based Costing (ABC) sets forth an innovative approach to assigning overhead and indirect costs to corresponding products and services. This methodology transcends traditional cost assignments by taking into account the complex relationship between costs, overhead activities, and products. Its implementation plays a key role in cost management and the development of sound financial strategies that help businesses to thrive, especially in the sphere of product manufacturing. When it comes to determining the most suitable cost accounting system for a business, evaluating the differences between activity-based costing (ABC) and traditional costing methods is essential. Both methods have their own distinct approaches to allocating overhead and indirect costs to products and services, which may offer varying levels of insights and accuracy for businesses. ABC is a comprehensive cost accounting system that identifies the relationship between costs, overhead activities, and production outputs.

- For instance, Intel upgraded its Celeron microprocessor chips to Pentium 1, 2, 3 and now 4.

- Costs allocated to each activity represent the resources consumed by it.

- To understand the full benefits of ABC, it is important to delve into its inception, development, and core principles.

- Implementing ABC analysis effectively can transform your inventory management system, making it more efficient and responsive to your operational needs.

- Imagine managing a warehouse with 10,000 different SKUs—from fast-moving bestsellers to items that gather dust for months.

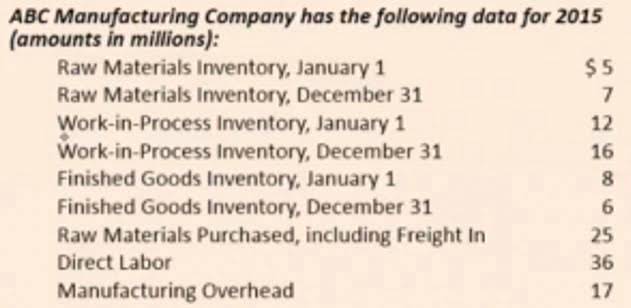

With the ABC method, cost drivers are identified to allocate costs accurately, enabling businesses to pinpoint the source of their overhead expenses. Now that we have understood the basic principles of Activity-Based Costing (ABC), let’s explore its application with a practical what are retained earnings costing scenario. Consider that traditional costing methods divide costs into product costs and period costs. The period costs include selling, general, and administrative items that are charged against income in the period incurred. Product costs are the familiar direct materials, direct labor, and factory overhead.

- In essence, the ABC Principle encourages procurement professionals to always have their end goal in mind and take proactive steps towards achieving it.

- The cost of such activities is driven by number of batches of units produced.

- This leads to more efficient operations and can significantly reduce waste and inefficiency in the supply chain.

- The concept of ABC was developed in the manufacturing sector of the United States during 1970s and 1980s.

- For retail locations, using dynamic repricing tools can adjust prices based on inventory categorization and real-time market demand.

ABC Analysis in Inventory Management: A Strategic Guide for Business Success

It means actively seeking opportunities for improvement instead of waiting for them to come your way. By employing this mindset in your procurement practices, you can ensure that every decision made aligns with your ultimate goal – whether it’s cost savings, supplier consolidation, or process efficiency. A classic example of ABC in action is its application in a healthcare setting. Hospitals often face challenges in allocating indirect costs, such as administrative support or facility maintenance, to individual departments or procedures. For example, all activities related to machine maintenance might form one cost pool. If we’re looking on atimeline drafted for one month, purchasing “A” items can be done weekly, “B”items in a bi-weekly frequency and “C” items every 4 weeks.

- Most of the wholesalers and distributors do not put this into practice and unfortunately, get a large number of working capital tied up in unhealthy inventories and products.

- Any cost that is identified to a particular product through its consumption of activity becomes direct cost of the product.

- When you use all three steps in any spoken or written message, people understand quickly and trust you.

- If its level changes, it brings a corresponding change in the level of total cost of the related cost object.

- For example the total costs of all set ups might constitute one cost centre for all setup related costs.

ABC, despite its broad application, might not be beneficial for all operations. Its implementation requires substantial effort to identify and cost every activity. Nonetheless, by pushing the boundaries of its conventional application, ABC has the potential to transform cost management across an array of industries and sectors. Examples are excellent learning tools, but understanding how to translate these examples into practice is a vital skill.

Why It’s Worthwhile to Do Quick Alphabet Sequencing Activities in Orton-Gillingham Lessons for Dyslexic Students

Automated systems also help maintain accurate records, crucial for effective ABC analysis. This methodical approach to prioritization not only streamlines processes but also enhances the overall inventory management system, making it more responsive to the actual needs of the business. As the main objective of ABC Analysis is a more effective inventory and warehouse management, we should implement different strategies for each group of stock items. So if we know that a group is far more important then the other, then we should focus our time, energy and money to the most important ones.

Unit-based cost systems apportion fixed overhead to individual products and variable overheads are directly assigned to products using the base of number of units produced. For instance, if one of your activities is handling customer service calls, a possible cost driver could be the number of calls attended. Costs related to customer service, such as salaries of service personnel and telephone charges, would be collected in that activity’s cost pool. You then use the cost abc principle definition driver (number of calls) to allocate the pooled costs to products or services based on their actual consumption of the activity.